Note: Some of the graphical elements of this site are only visible to browsers that support accepted web standards. The content of this site is, however, accessible to any browser or Internet device.

ULTRASONIC COUPLANTS

Hydrophilic polymers for dry-coupling inspection

Applied to nondestructive testing they have the following advantages compared to conventional coupling mediums:

|

|

|

Unlike conventional dry couplants normally used as an integral part of ultrasonic probes (e.g. rubbers) this elastomer can be applied independently of the probe.

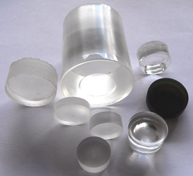

Hydrophilic couplants are available in many sizes and thicknesses, and custom shape designs are also available.

Especially designed couplants based on hydrophilic polymers have superb ultrasonic characteristics. The soft gel-like surface of these materials gives the opportunity for establishing good and continuous acoustic contact to the inspected part without the need of additional coupling liquids. These materials conform very well to rough and geometrically complex surfaces.

Acoustic impedance of the hydrophilic couplants is near to that of immersion liquid and their attenuation coefficient is lower than all other documented elastomers and many plastics. Depending on the type of hydrophilic material and the liquid that it is swelled the operating temperature range of the device can be extended from - 30° C up to 70° C and inspection with frequencies as high as 25 MHz can be achieved.

Low price

Low price